Additional notes added August

2019

|

| © 2017 David Hurst All Rights Reserved |

This is a small tram-style coach based on the Clogher Valley

Railways coaches but without the clerestory roof.

The original Clogher Valley coaches were built in 1886 by

The Metropolitan Railway Carriage and Wagon Co of Birmingham. There were 13

passenger coaches in total, numbers 7-9 bogie 1st class which were shorter

than the others, 10 & 11 bogie 1st / 3rd composite,

12 – 19 bogie 3rd. All the coaches had balconies at each end, which

supported the overhanging clerestory style roof. Communication between each

coach was possible across metal fall-plates which covered the buffer-couplings.

The carriages were innovative in using exhaust steam to provide heat to their passengers,

at a time when the best most people could expect in winter was a warming pan.

The coaches remained in service till the lines closure on New Year’s Day

1942.

| © 2017 David Hurst All Rights Reserved |

The print configuration in two halves cuts down the amount

of support material by a considerable amount and therefore the cost. It still

allows for the fitting of internal details and glazing before the coach is

assembled. It is also much easier to add details such as the etched mesh to the

balcony end frames from the inside before they are added to the main coachwork.

Because of the detailed panel-work on these coaches they are

only available to print in Frosted Ultra Detail, this does mean that the

balcony end frames are quite delicate and I have found that they may warp in

transit. Fixing them into position on the model does push them back into their

correct shape, but be gentle as this is done.

| © 2017 David Hurst All Rights Reserved |

| © 2017 David Hurst All Rights Reserved |

I decided to use a pair of Kato 11-099 bogies on this coach

as they have an offset pivot, are small well engineered and have a free running

wheel sets. The offset pivot on the bogie was particularly useful as it allowed

the pivot on the floor of the coach to be close to the balcony steps without

the bogie being restricted by them. This does mean that they are the wrong way

round, the couplings facing inward, and should be removed. I felt that this

would not be of any detriment as the coach itself is short, and normal fixed coupling

should cope on restricted curves. I did find that the pivot formed by the

printer can vary in the thickness. This stops the free movement of the bogie

from side to side. I used a small flat file to dress off some access material

at the base of the pivot on the coach, which will allow the pivot clips on the

bogie to engage on the inside of the pivot hole on the bottom of the coach and

allow it to turn freely.

My choice of finish was a Revel oil based paint ref SM 331

thinned slightly and I applied two coats of this to the sides, ends and the

balcony ends. The frames and steps had a coat of dark grey Revel mat 9, the

fall plates were a mix of the matt 9 and a silver to create a dark gunmetal

finish. A wood colour mix was used on the balcony floors, and on the roof I

used a Revel light grey matt 43 and white 5 mix. I left the inside of the coach

in the light grey primer finish as this is pretty neutral.

|

| © 2017 David Hurst All Rights Reserved |

After the painting was completed, the glazing could be added

with a sheet of clear acetate cut to suit the side windows, then glued in place

with Cyanoacrylate glue (super glue). I found it simplest to position the

glazing panels and then drop some glue on the edges, this would then run under

the acetate and fix it in place. Apply a little light pressure while the glue

is going off.

|

| © 2017 David Hurst All Rights Reserved |

When you are assembling the coach the central roof joint

will be the most obvious and this can be tackled in a few ways. One is to fill

the joint after fixing the coach together and painting over the joint. Another

method is to use a single lamination of toilet tissue paper to represent a felt

roof covering: fill the roof joint, apply glue over the whole roof, then add the

paper from the centre line letting the glue soak in as it is applied. Once the

result has dried this can be painted, possibly in a dark grey to mimic the felt

colour. The two roof ventilators are then added and finished in with the roof

colouring.

Numbers were added

to each side of this particular coach. The central panel was used to display

the number 10, the three panels under the windows being a good area to display

numbering or lettering. Any style of around 1 to 2mm size will look fine. I used the Fox Transfers FG1003 -

Alphabet in white - Franklin Heavy, 2mm & 1mm which give a nice bold graphic.

|

| © 2017 David Hurst All Rights Reserved |

Once fully assembled – couplings added, glazing and painting

fully completed- a coat of thinned matt or satin varnish was applied to all

painted areas of the model. This helps to fix the transfers and pull the whole

finish together. It is a bit of a personal choice, but I do like to add a

measure of weathering to the final model. It removes that out- of- the box

look. To do this I use artist’s oil pastels which have been made into a powder

form. Black, burnt senna (earth/mid brown), light red and orange are the main

colour pallet that I use. It is also

quite easy to mix these to create other shades. They are dusted on the model

with a number 6 size paint brush that is kept specifically for this job. If you

don’t like what you have done it can be cleaned off again, which is what I like

about using oil pastel dust to do the weathering.

|

| © 2017 David Hurst All Rights Reserved |

|

| © 2017 David Hurst All Rights Reserved |

If you would like a copy of this model visit Model Engine Works at:

Additional notes added August

2019

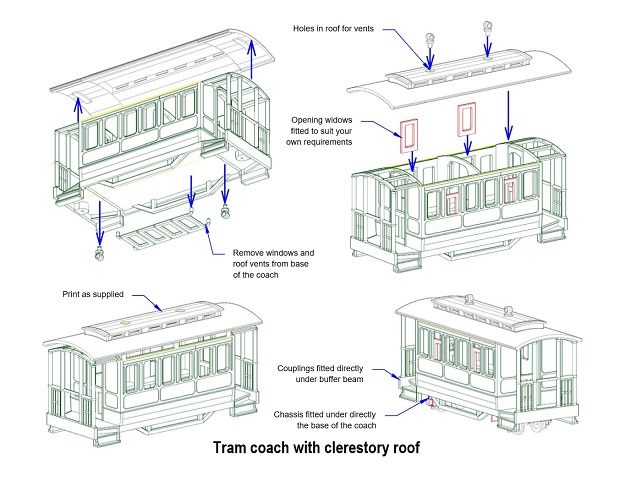

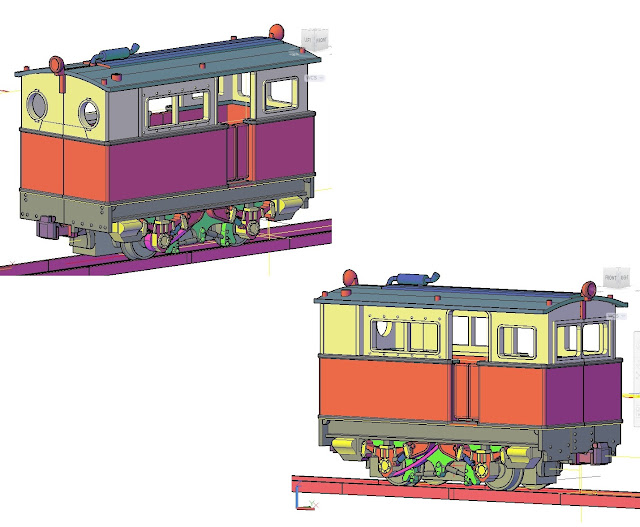

Further variants of this style

of coach are available from the Model Engine Works Shop on Shapeways. Both are

slightly smaller and more economical to build. One comes with a clerestory

roof like the original Clogher Valley coaches. The other has no roof printed,

allowing you to supply your own. They both have window openers which can be

positioned as you require. Roof vents are also supplied to add the finishing

touch to the roof.

|

© 2019 David

Hurst All Rights Reserved

|

|

© 2019 David

Hurst All Rights Reserved

|

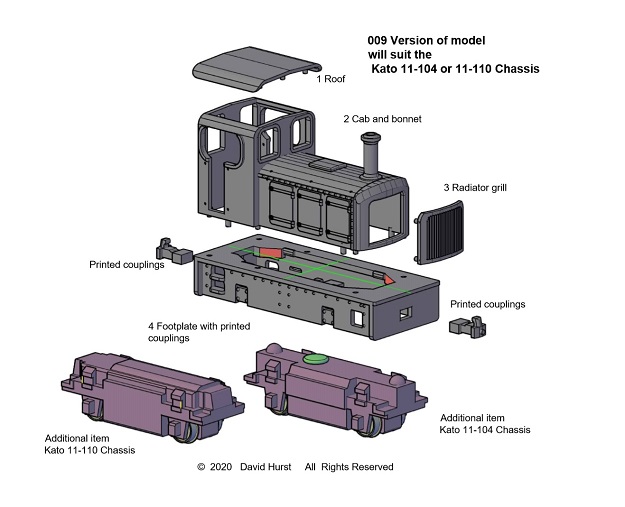

Further items will be need to complete the models, these

include wagon chassis such as the Peco N" gauge chassis kits (Ref

NR122 0r NR123) from Dundas Models. A set of couplings and acetate or clear

Plasticard for glazing the windows.

|

© 2019 David

Hurst All Rights Reserved

|

If you would like a copy of this model visit Model Engine Works at: